Engineering Performance Without Compromise

SERVICES

At RIVAL AUTOHAUS, our services are built around precision, data, and advanced manufacturing. Every component we design or produce follows a digital-first workflow that ensures exact fitment, superior performance, and production-grade quality.

3d Scanning Services

Our 3D scanning services capture complex automotive parts and assemblies with high-resolution accuracy, allowing us to recreate physical components as precise digital models. This enables reverse engineering, CAD refinement, prototyping, and seamless integration into custom fabrication workflows.

We scan everything from body panels, bumpers, and aero components to exhaust systems, brackets, and engine bay geometry. Each scan becomes the foundation for engineered parts designed for perfect fitment, optimized performance, and repeatable manufacturing — whether produced through CNC machining or metal and composite 3D printing.

Metal & Composite 3D Printing

Our metal and composite 3D printing services provide a modern manufacturing solution for producing high-performance automotive components with exceptional precision and consistency. Additive manufacturing builds parts layer by layer from engineered digital models, allowing for complex geometries, integrated features, and optimized structures that are not achievable through traditional fabrication methods.

Metal 3D printing enables the production of strong, heat-resistant components using materials such as stainless steel, titanium, Inconel, and aluminum. These materials are ideal for exhaust components, brackets, mounts, housings, and structural parts that must withstand high temperatures, vibration, and mechanical load.

Composite plastic 3D printing focuses on lightweight, durable components using high-performance polymers and fiber-reinforced materials. This process is well-suited for ducting, housings, interior parts, functional prototypes, and low-volume production components where strength-to-weight efficiency and precision fitment are critical.

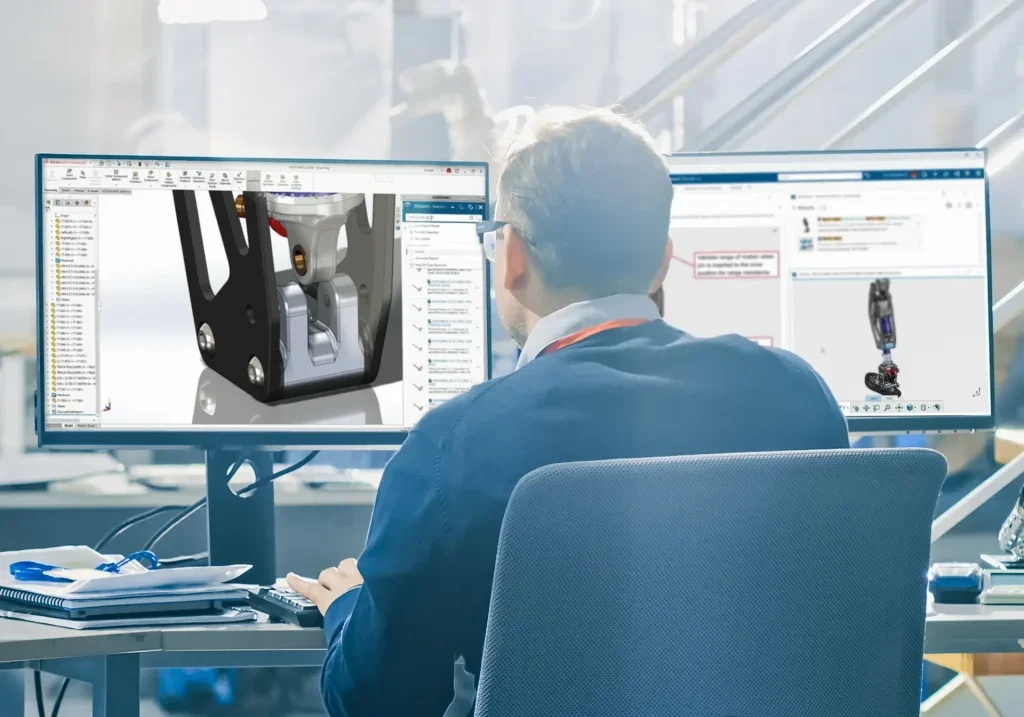

CAD Design, Reverse Engineering & CFD Simulation

Our CAD design and reverse engineering services convert physical components and concepts into precise, production-ready digital models. Each part is developed with engineering intent, focusing on fitment, flow efficiency, strength, and manufacturability. This process provides a controlled, data-driven foundation for performance-focused automotive development.

We incorporate Computational Fluid Dynamics (CFD) simulation to analyze airflow, pressure distribution, and velocity across components such as exhaust systems, ducting, aero elements, and under-body structures. CFD allows us to validate and refine designs digitally, optimizing performance before any material is manufactured.

This service is ideal for motorsport applications, custom builds, and legacy OEM parts where factory data is unavailable. By combining CAD, reverse engineering, and CFD analysis, we reduce development time, eliminate guesswork, and deliver engineered solutions designed for accuracy, efficiency, and repeatability

READY TO BUILD?

Whether you’re developing a custom performance component or engineering a complete system, RIVAL AUTOHAUS delivers precision without compromise.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!

Rivalautohaus@gmail.com